Russian Civil Aviation: News #4

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°326

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

dino00, JohninMK, LMFS and lancelot like this post

PhSt- Posts : 1203

Points : 1209

Join date : 2019-04-02

Location : Canada

- Post n°327

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

medo, George1, dino00, xeno, Maximmmm, tomazy, LMFS and like this post

owais.usmani- Posts : 1786

Points : 1782

Join date : 2019-03-27

Age : 37

- Post n°328

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

Experienced MS-21-310, equipped with Russian PD-14 engines, arrived in Zhukovsky

Lots of good pictures.

GarryB and LMFS like this post

Kiko- Posts : 2839

Points : 2883

Join date : 2020-11-11

Age : 75

Location : Brasilia

- Post n°329

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

The Ministry of Industry and Trade has prepared a plan to enter the market and support sales of 735 domestic aircraft for 1.8 trillion rubles, media reported.

The Ministry of Industry and Trade has developed a plan for creating a line of “competitive products of the aviation industry,” writes Kommersant . The project, which should be included in the new strategy for the socio-economic development of the Russian Federation until 2030, provides for the production of 735 new civil aircraft. First of all, we are talking about the introduction of the Il-114, MS-21 and Baikal (LMS-901) to the market. Also in the plans for the delivery of the project passport dated May 28, Sukhoi Superjet 100, L-410 and five types of helicopters appear.

The ministry expects that this will ensure the purchase of Russian aircraft by state-owned airlines and will increase the utilization of the civilian segment of the industry's industrial enterprises to 80-90%.

The total revenues from taxes and fees of the aircraft delivery program reached 450 billion rubles by the end of the period, the document says.

The implementation of the project will require about 1.84 trillion rubles for 2021–2030. About 244 billion rubles of this amount is from the federal budget, and a third (79.48 billion rubles) is listed as already provided, but the Ministry of Industry and Trade proposes to additionally allocate 165 billion rubles from the budget in 2025–2030.

The bulk of the funds - more than 1.59 trillion rubles - is planned to be attracted by 2030 from the NWF. This year we are talking about 9.4 billion rubles. They want to attract another 537.9 billion rubles by 2024, over 1 trillion rubles - from 2025 to 2030. By the end of 2022, the program assumes the production of 36 MC-21 aircraft per year and the start of serial deliveries. By December 2027, Irkut is to deliver 120 aircraft and produce 72 aircraft per year. In December 2023, it is planned to certify the MC-21 in EASA.

Recall that in May, the head of the department Denis Manturov said that the Ministry of Industry and Trade expects that the domestic MS-21 passenger aircraft with a Russian wing will take to the skies by the end of 2021.

Text: Dmitry Zubarev

https://m.vz.ru/news/2021/7/12/1108458.html

dino00, JohninMK, LMFS, Hole, Scorpius and Russian_Patriot_ like this post

Kiko- Posts : 2839

Points : 2883

Join date : 2020-11-11

Age : 75

Location : Brasilia

- Post n°330

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

MAKS-2021 is approaching. Journalists are preparing for the air show, writing relevant articles. The site "Aviation of Russia" received a request from one of the central publications with a request to comment on the MC-21 and Il-114-300 programs. Below we offer comments by the editor-in-chief of the site, Andrey Velichko, on the MC-21 medium-haul liner.

Question: From the very beginning, it was planned that the share of domestic components in MS-21 would be at least 38% with further growth. What is the approximate percentage of Russian spare parts on this aircraft now?

Answer: Irkut spoke about 40 percent of Russian components back in 2016, then it was clarified that this was taking into account the equipment of the aircraft with the PD-14 engine. Now, when we can already say that all units made of imported composites have been replaced, the percentage of domestic components has grown significantly. Irkut has not yet named specific figures, but it can be assumed that with PD-14 this is 55-60%.

Q: Now Russian companies are working on the airliner avionics in order to replace imported components with their own as much as possible. How do they do it and what is the most difficult thing to do? How promising and competitive will these systems be compared to Western models?

A: The MS-21 avionics are a complex of Russian-French-American equipment, of which, first of all, import substitution is required by the American one. Considering that KRET has extensive experience in creating aircraft systems, as well as the fact that the concern serially produces IVK-KSU-MS-21, upon receipt of an application for the development of additional electronic components, the concern will not have any difficulties. And do not forget that the MC-21 stands apart among its "classmates" in terms of aircraft control. It uses an active side handle... Neither Airbus, let alone Boeing, use such technology in their airliners. The integration of onboard equipment from different suppliers is carried out by UAC-Integration Center. Avionics MS-21 will not fundamentally differ from similar equipment Airbus, Boeing, Embraer or COMAC. And from the point of view of flight safety, if an aircraft receives a type certificate, it means that it meets all the requirements of aviation regulations.

Q: MS-21 has the largest percentage of composites among Russian vehicles - 35. It is known about the "black wing". What else did domestic manufacturers have to re-develop from composites? How high-quality were the new parts and how did they show themselves in tests?

A: The most important thing that had to be re-created was carbon fiber of the required strength level. Over the past 30 years, the entire scientific and technical groundwork for PCM, which was accumulated in the USSR, has been used. Relying on international cooperation, new domestic technologies in the production of composite materials were not created. However, what was saved after the 90s has now yielded results in the form of domestic materials that can be used in the power units of modern passenger aircraft.

According to the import substitution program, signed on April 28, 2020 between the Ministry of Industry and Trade and the Irkut corporation, by the end of 2020 the contractor had to select Russian-made materials and work out the technologies for manufacturing MC-21 units from them, including the wing console. By the end of 2021, it is necessary to prepare a test base and conduct tests of the wing console and mechanization elements made from Russian PKM. The installation of the first wing console on an aircraft indicates that the results of the tests already carried out make it possible to install the wing on a production aircraft.

As for quality, another point is important here. After the supply of PCM was stopped, the MC-21 developers had to look for a replacement for imported fibers. The main problem was that the Russian analog had to be absolutely identical to the fibers from which the wing consoles and other power units of the MC-21 experimental aircraft undergoing certification were already made, otherwise the entire test cycle would have to be started anew. Now it is enough to certify only Russian composite materials, the wing itself is structurally identical to a product made of imported PCM and corresponds to the parameters specified in the technical specification.

Q: The PD-14, the first domestic aircraft engine in 30 years, is installed on the MS-21-310. What problems have arisen in the process of its development and certification?

A: When it comes to PD-14, they usually talk about various technical details. For PD-14, 16 critical technologies were developed , including: single-crystal blades of a high-pressure turbine with a promising cooling system, operable at gas temperatures up to 2000 ° K, a hollow wide-chord titanium alloy fan blade, thanks to which it was possible to increase the efficiency of the fan stage by 5 % compared to PS-90, low-emission combustion chamber made of intermetallic alloy, sound-absorbing structures made of composite materials, ceramic coatings on hot part parts, hollow blades of a low-pressure turbine.

Q: How promising is it compared to the engines of Western companies, and how quickly will they be able to put it into production?

A : Why is he not? Why do we deny professionalism to the designers of the Yakovlev Design Bureau and UEC-Aviadvigatel? Indeed, for the aircraft to be competitive in economic, environmental, traction and resource parameters, the PW1400 and PD-14 engines must be similar. There is a technical assignment for the aircraft, in which the operational parameters and technical characteristics are detailed. It is impossible to offer the same type of aircraft, for which the released models will differ from each other in their TX due to the fact that two different engines are used. This is absurd. Therefore, PD-14 is an absolutely competitive product, otherwise, why was it necessary to start developing it and spend billions of rubles on it?

The PD-14 series has already been launched. In February this year, "UEC-Perm Motors" received a certificate that gives the right to serial production of PD-14. Another question is how soon Perm will be able to produce the required number of power plants? Indeed, in addition to products intended for installation on an aircraft, it is necessary to produce replacement engines. Therefore, the first production vehicles will go with the PW1400, building the MS-21 with the PD-14, obviously, will be on the rise as the serial production of power plants increases.

Q: Experts note that it will be extremely difficult for our aircraft to enter the world market by 2025 - 75% of the market is contracted by aircraft from Airbus and Boeing. Does the MS-21 have real prospects for conquering the world market and with which machines will it have to compete?

A:It is unrealistic to conquer the world market in the foreseeable future. One aircraft plant in Irkutsk cannot compete in terms of production of the MC-21 with dozens of Boeing and Airbus plants around the world. If someone thinks otherwise, then this is a project and empty promises. First of all, the aircraft should replace the A320 / 321 and B737 in our domestic market, but it is obvious that airlines will not massively change their imported equipment for MS-21, many of the aircraft are not old, there are contractual obligations to lessors and manufacturers, liners are not supplied immediately after signing the contract, some of the aircraft have already been purchased and new ones are not needed yet. Therefore, first of all, aircraft that are older, less economical, and decommissioning will require replacement. Well, the state-owned company, in this case - "Russia", will begin to run in new equipment by tradition.

Q: What countries should we count on? How competitive will the MC-21 be at the time of production?

A: Most likely, the liner will be offered to the EAEU countries, as well as the former republics that are not part of the Customs Union: Uzbekistan, Tajikistan, Azerbaijan and states historically friendly to Russia in Asia and Africa. But at the same time, it should be borne in mind that it will be very difficult to sell the MS-21 abroad, because in addition to solving issues of service and after-sales service, providing spare parts, you will have to overcome the dumping of concerns A and B, as well as the local lobby fed by them. This is another argument that conquering the global market will be an almost impossible task. In the future, you can count on 4-6 percent.

Q: Will it be possible, in your opinion, to bring the share of domestic components to 97% by 2022, as stated, or is it impossible? And in general, is there such a potential opportunity to produce completely all components within the country and is there a need for this?

A: There is a potential and the 97 percent level is quite achievable, but I think that it is enough to bring import substitution to 80-90 percent. Now Irkut is almost monthlyholds tendersfor the development of aircraft systems, equipment and assemblies for the MS-21. Another question is whether it is necessary to completely replace imported components? Most probably not. This plane is not planned to be used in the interests of the Ministry of Defense or to carry the country's top officials on it. This is a purely commercial product. Therefore, there will be no 100% import substitution on it.

https://aviation21.ru/ms-21-kompozity-importozameshhenie-i-pd-14/

dino00, kvs, LMFS and Russian_Patriot_ like this post

Hole- Posts : 10722

Points : 10700

Join date : 2018-03-24

Age : 47

Location : Scholzistan

- Post n°331

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

dino00, kvs, LMFS and Russian_Patriot_ like this post

Kiko- Posts : 2839

Points : 2883

Join date : 2020-11-11

Age : 75

Location : Brasilia

- Post n°332

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

On July 14, 2021, the docking of the left wing console to the fuselage of the MC-21-300 aircraft was completed at the Irkut Corporation PJSC (Rostec) plant. Previously, the center section and the right wing console were installed on it. The aircraft is intended for delivery to the first customer.

The wing consoles and center section are made of Russian polymer composite materials at the AeroComposite-Ulyanovsk enterprise. In the near future, the specialists of the Irkutsk Aviation Plant will start assembling the aircraft systems. Domestic materials for the production of composite structures were developed with the participation of Moscow State University and Rosatom enterprises.

The wing is manufactured using vacuum infusion technology, which is patented in Russia. The use of rigid and lightweight composite materials made it possible to develop a wing of high aspect ratio and improve the aerodynamics of the MC-21 aircraft, which, in turn, made it possible to increase the diameter of the fuselage to increase the comfort of passengers.

https://sdelanounas.ru/blogs/142339/

dino00, kvs, LMFS, Hole and Russian_Patriot_ like this post

Rodion_Romanovic- Posts : 2414

Points : 2581

Join date : 2015-12-30

Location : Merkelland

- Post n°333

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

UEC-Klimov will develop an engine for the TVRS-44 aircraft

St. Petersburg UEC-Klimov received a technical assignment for the creation of the TV7-117ST-02 engine for the TVRS-44 regional turboprop aircraft. At the moment, pre-contract work is underway. It is planned to start serial production of new power plants in 2025, the press service of the UEC reported.

The engine modification will be created on the basis of the TV7-117ST-01 power plant undergoing certification for the Il-114-300 aircraft. Modification -02 will have a takeoff power of 2400 hp. and reduced fuel consumption. Unlike the base engine, the TV7-117ST-02 will receive a closed oil system and a new aircraft generator with a higher rotational speed to reduce weight.

Other differences of the new power plant will be an electric start instead of an air one (a modern starter-generator will be used), as well as updated piping, an electrical system, and an automatic regulation and control unit design. In addition, the engine mounts will be adapted for the under-wing suspension on the aircraft.

“The project being implemented meets two global goals - it contributes to the development of domestic competencies in the field of civil aircraft construction and the satisfaction of the country's needs in regional aviation. We plan to produce the first prototypes for preliminary tests by mid-2023, and at the end of 2023 - to supply engines to TVRS for flight tests. Serial production of TV7-117ST-02 is planned to begin in 2025, ”noted Vsevolod Eliseev, General Designer of UEC-Klimov JSC.

TVRS-44 is a regional turboprop passenger aircraft in the 40-50-seat class designed to replace the outdated An-24, Yak-40, An-26B-100 fleet. Created by the Ural Civil Aviation Plant on the basis of the Czech L-610.

So the aircraft is not a mindless copy of a L610, it will be a Russian aircraft with a Russian name that the uses the design effort of the L610 as a starting point for its development (and the development of the L610 was financed by soviet union anyway). Furthermore I believe it fits quite well in the regional aircraft requirement of Russia and other countries, and integrate quite well with the larger il114 (which is a faster, low wing aircraft in the 60 -70seat class)

GarryB, kvs, LMFS and Russian_Patriot_ like this post

Kiko- Posts : 2839

Points : 2883

Join date : 2020-11-11

Age : 75

Location : Brasilia

- Post n°334

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

According to Yuri Slyusar, the production level will be raised to 36 airplanes by 2025 and then should be doubled by 2027.

MOSCOW, July 15. /TASS/. The United Aircraft Corporation (UAC) will produce 36 MC-21 airplanes per year by 2025, CEO Yuri Slyusar said at the meeting with Russian President Vladimir Putin.

"One of our key tasks, and this is also a process task, is to raise the production level to 36 airplanes by 2025 and then we should reach the level of 72 [aircraft] in two years," Slyusar said.

The airplane completed over 500 test flights to date, the executive said.

"As regards the MC-21, over 500 flights were made. The flight and bench test program is implemented. The wing, made of domestic composites, has recently passed one of its key tests," he noted.

The domestic market capacity for narrow-body long-distance aircraft will be about 600 airplanes per year over the next nine years and UAC expects to capture a significant share of this market, Slyusar said.

The MC-21 is a Russian medium-range passenger jet currently under development. There are two engine configurations available, and the version with PW140 engines is already undergoing certification tests.

https://tass.com/economy/1314369

GarryB, dino00, kvs, LMFS, Rasisuki Nebia and Russian_Patriot_ like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°335

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

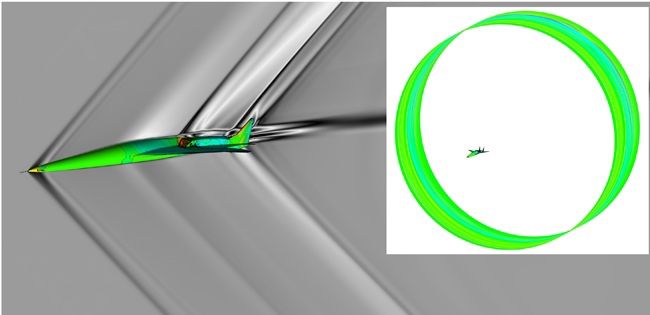

A large-scale model of the Strizh supersonic civil aircraft technology demonstrator will become the main exhibit of the Zhukovsky Central Aerohydrodynamic Institute (part of the Zhukovsky Institute) at the MAKS-2021 International Aerospace Salon. This and other innovative developments in the field of supersonic passenger aviation will be shown at the joint exhibition of organizations that are part of the Zhukovsky Institute Research Center.

The supersonic passenger aircraft layout reflects a number of fundamentally new developments of domestic scientists. Its layout has a low sound impact level while providing high aerodynamic characteristics, stability and controllability over the entire range of flight modes. An innovative metal-composite structural-power scheme is created using bionic principles. The use of alternative materials in the GHS design promises undeniable advantages in reducing the weight of the aircraft and saving fuel. Two mock-ups of the structural and power scheme-fragments of the nose and back parts of a promising aircraft-will illustrate the work of TsAGI scientists in this direction.

A logical continuation of the supersonic theme will be the accompanying exhibition samples — a pipe model of an isolated air intake and a nozzle model with a noise reduction system for an acoustic stand.

A mock-up of an aerobatic stand with a cantilever mobility system will also be presented to the general public. It allows you to clearly show the technological capabilities of development within the framework of the project "NCMU "Supersonic". The demonstrator includes a robot manipulator with a computing unit, a lightweight scale capsule-a mock-up of the crew cabin, and a computational modeling complex.

Source:

GarryB, dino00, LMFS, Hole and Backman like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°336

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

The Yak-18T with the APD-500 aircraft piston engine will soon be shown at MAKS-2021.

For several years, the Central Institute of Aviation Engine Building named after P. I. Baranov (CIAM, part of the SIC "Zhukovsky Institute") was engaged in adapting this engine for ultra-small aircraft. Experts also tested the aviation version of the Aurus engine.

Now CIAM has announced the completion of the installation of the APD-500 aircraft piston engine demonstrator on the Yak-18T aircraft. Yak-18T equipped with APD-500 will be demonstrated at the International Aviation and Space Salon. The first flight tests are scheduled for the second half of 2021.

A number of new components and systems have been developed for the APD-500 8-cylinder V-shaped engine (500 hp). For example, a starter-generator, a gearbox (designed for the use of propellers), a two-channel engine control system with independent circuits, a supercharging system with a drive supercharger.

"The domestic piston engine is an opportunity to" reset " the entire small aviation industry in Russia. It will be able to find the widest possible application, give an impetus to the remotorization and creation of new aircraft, " says Mikhail Gordin, General Director of CIAM.

The main task of the research work "Adaptation" is to confirm the possibility of creating an aircraft engine based on a mass-produced automobile engine, to assess the advantages of its creation in terms of time and cost. The work is being carried out by order of the Ministry of Industry and Trade of Russia.

Source:

GarryB, dino00, kvs and LMFS like this post

dino00- Posts : 1677

Points : 1714

Join date : 2012-10-12

Age : 36

Location : portugal

- Post n°337

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

GarryB, Big_Gazza, LMFS, Backman, Rasisuki Nebia and Russian_Patriot_ like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°338

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

flamming_python, LMFS, Lynx and Daniel_Admassu like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°339

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

GarryB, flamming_python, xeno, x_54_u43, LMFS, Lynx and Kiko like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°340

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

15 SSJ100 for Rossiya

25 SSJ100 for Red Wings

10 SSJ100 for Azimuth

An agreement was also signed on the commissioning of the MS-21 at Rossiya Airlines

LMFS, Hole, owais.usmani and Lynx like this post

Backman- Posts : 2602

Points : 2614

Join date : 2020-11-11

- Post n°341

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

PapaDragon- Posts : 13272

Points : 13314

Join date : 2015-04-26

Location : Fort Evil, Serbia

- Post n°342

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

Backman wrote:Let's see the SST FFS

SST?

Hole- Posts : 10722

Points : 10700

Join date : 2018-03-24

Age : 47

Location : Scholzistan

- Post n°343

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

Backman likes this post

GarryB- Posts : 38984

Points : 39480

Join date : 2010-03-30

Location : New Zealand

- Post n°345

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

Prototype with foreign engine because it is available and is in a suitable power range, but local engine for production and domestic use, when it is ready.

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°346

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°347

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

This plane is eagerly awaited and in Russia, and in Kazakhstan, and in many countries of the world. Where there are no mainline liners and no trains, a simple, reliable, inexpensive and efficient aircraft is required that can land on a small lawn, take passengers and their luggage on board and safely deliver them to a district or regional center.

Such a machine has already been designed by the Ural Civil Aviation Plant. And two companies will build Baikal: UZGA and"Kazakhstan Aviation Industry. The corresponding agreement was signed today at the MAKS-2021. According to the agreement, Kazakhstan Aviation Industry acquired 20% in the company "Baikal-Engineering", which creates the Baikal aircraft.

Source: MAKS group in VKontakte social network

LMFS likes this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°348

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

dino00, LMFS and Hole like this post

flamming_python- Posts : 8988

Points : 9050

Join date : 2012-01-30

- Post n°349

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

dino00, LMFS and Russian_Patriot_ like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°350

Re: Russian Civil Aviation: News #4

Re: Russian Civil Aviation: News #4

As part of the business program of the International Aviation and Space Salon, IL of the United Aircraft Corporation, the State Transport Leasing Company and Aurora Airlines signed an agreement of intent for the supply of 19 regional IL-114-300 aircraft. Deliveries of the aircraft are scheduled to begin in 2023.

The new regional IL-114-300s will be delivered as part of the program to improve transport accessibility in the Far East and are designed to help increase the intensity of air traffic, as well as large-scale renewal and increase the fleet in the region.

"The appearance of such an aircraft as the IL-114-300 in Russia is extremely important. This is a fully domestic passenger turboprop aircraft that will be able to provide air mobility of the population in hard-to-reach areas of the North, Far East and Siberia. Therefore, this program is a priority for us" said Sergey Yarkov, First Deputy General Director of UAC, Managing Director of PJSC Il. – "The first prototype of the aircraft is currently participating in flight tests. IL-114-300s are being assembled in Lukhovitsy using serial technologies. Taking into account the technical capabilities of the site, it is possible to produce about 12 cars per year. Our order portfolio is growing. At the start of the program, we estimated the market at 100 aircraft, and due to special versions, the potential demand can be increased to 150 aircraft."

"Developing demand for domestic aircraft products is one of the main tasks of STLC in the Russian market. In addition to the Superjet 100 aircraft, the latest Russian Mi-8 and Ansat helicopters, the range of STLC offers is being expanded with the advanced IL-114-300 aircraft"said Anton Korolev, Deputy General Director of STLC. – "The signed agreement will help to increase the level of connectivity of our country's territories and transport accessibility of the regions. We look forward to long-term and effective cooperation with UAC and Aurora Airlines for the benefit of the entire Russian transport industry."

The IL-114-300 is presented for the first time at the MAKS-2021 International Aviation and Space Salon. This is a regional passenger turboprop aircraft that is designed for local airlines and can be operated in regions with weak airfield infrastructure and difficult climatic conditions. It will replace retired AN-24 and AN-26 family aircraft on domestic airlines and will become an alternative to imported aircraft of the same class. The IL-114-300 is specially designed for autonomous operation in the conditions of Russian airports, taking into account climatic zones.

Source:

Last edited by Russian_Patriot_ on Fri Jul 23, 2021 4:16 am; edited 1 time in total

dino00, LMFS and Russian_Patriot_ like this post

|

|

|

owais.usmani

owais.usmani